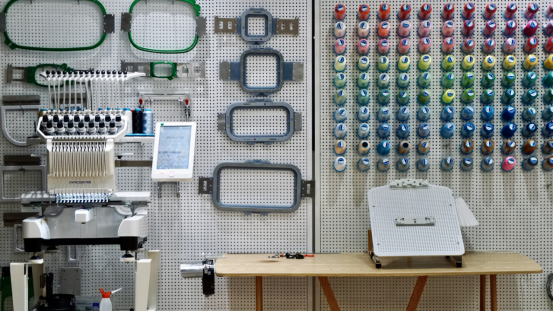

As a factory that has been producing computerized embroidery machines for 30 years, Proemb understands that a stable embroidery machine is the foundation for producing efficient and exquisite embroidery. Scientific and reasonable maintenance is the key to keeping machines in the best condition at all times. Whether it is a novice user who has just started using embroidery machines or a long-term enterprise engaged in embroidery production, mastering the correct maintenance methods can effectively reduce the failure rate, extend the service life of equipment, and reduce production losses caused by machine problems. Today we will introduce to you how to maintain our Proemb embroidery machine.

1.Daily cleaning

Clean up excess embroidery thread garbage and dust: After each use, use a soft bristled brush or vacuum cleaner to clean the thread debris and dust on the surface of the machine, especially on the needle board, shuttle bed, and thread path.

Cleaning needle board: Regularly remove the needle board, clean the garbage below, and prevent blockage.

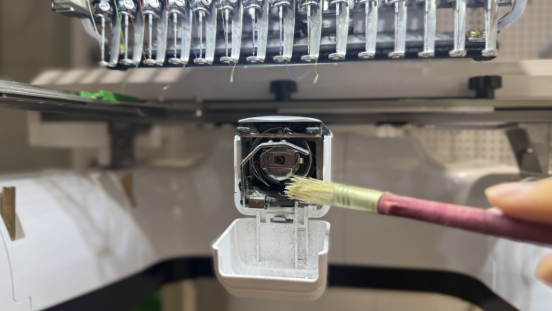

Cleaning the shuttle bed: Regularly clean the garbage and oil stains inside the shuttle bed to ensure smooth operation.

2.Lubrication and maintenance

Regular refueling: According to the frequency of use, regularly lubricate the frequently working parts of the machine, such as the spindle, connecting rod, shuttle bed, etc. Use specialized sewing machine oil and avoid using other types of lubricants.

Tips for refueling: Do not refuel excessively to avoid oil stains from contaminating fabrics or the interior of the machine.

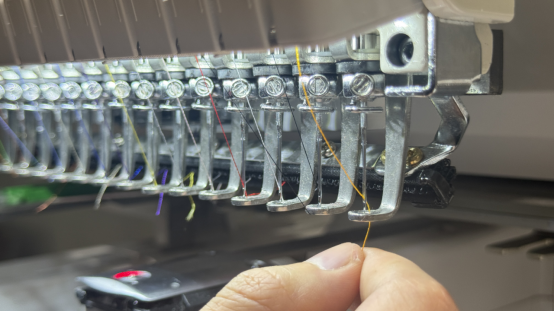

3. Check the needle and thread

Regularly replace the needles of the machine: The needles of the machine will become dull or bent after prolonged use, affecting the quality of embroidery.

Use appropriate thread: Choose embroidery thread suitable for the embroidery machine, avoid using low-quality embroidery thread, and prevent the machine from breaking or jamming the thread.

4. Adjust tension

Check thread tension: Regularly check the tension of the upper and lower threads to ensure even trajectory of the embroidery thread during embroidery. If the embroidery is found to be too tight or too loose, adjust the tension knob in a timely manner.

Adjust the tension of the bottom line: Inappropriate tension of the bottom line can lead to poor embroidery effect. Regularly check and adjust the tension of the shuttle core.

5. Regular professional maintenance

Annual comprehensive inspection: Even with proper daily maintenance, it is recommended to have professional technicians conduct a comprehensive inspection and maintenance of the embroidery machine once a year to ensure that all components are in good condition.